Tender Bed Modification

The tender bed is a fine aluminum casting supplied by Jim Kreider. overtime builders have started using a model of a Franklin radial buffer to replicate the full size version fitted to the locomotive. This after market casting set was supplied by Railroad supply in America.

Over the years I have seen this buffer applied to a number of Jim's Berkshires, however I was never very happy about the fitting of the buffer to the tender. This was due to the way it was attached and what I noticed was often there was damage to the aluminum face where the buffer was attached by two studs. This was due I believe to the hammering action between the tender bed and the locomotive. So I decided a small modification was in order to make the impact area a bit more secure.

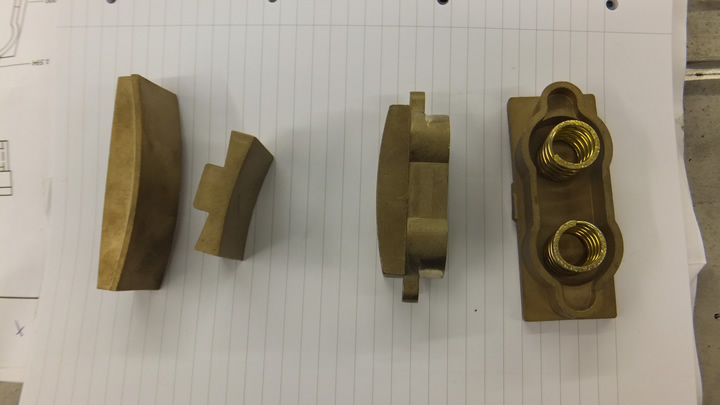

Buffer casting set

I took this snap on a trip not sure where now but this was what got me thinking about damage to the front face of the bed.

Generally the buffer is secured to the bed by two

4mm studs, screwed into the bed face. However by the time you get the

studs fitted there is very little surface area to carry the impact, and

what there is, is made of aluminum. So what I wanted was some way to get

the load carried by the bed not just the small area round the stud holes.

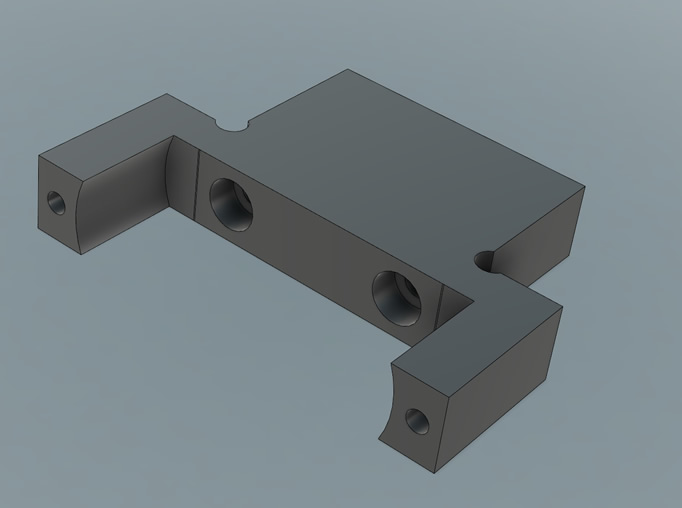

After a bit of measuring I came up with this design in steel.

Buffer carrier insert in steel

So after a bit of doodling in Fusion 360 and measurement of the bed I had worked out a suitable carrier to hold the buffer and transfer the load through into the bed proper.

This meant i needed to machine the existing cavity base and drill two 5mm tapped holes and machine out a 5/8 slot in the cavity walls. The Bed is about 5ft long X 20" wide. I could do this on my Bridgeport mill, but it meant removing the power draw bar so i could fit the right angle milling head. This all seemed like to much trouble , so it was off to John Dunn's who has a nice sized horizontal borer just made for the job.

.jpg)

Bed on the machine with the slot in the nose visible

.jpg)

Nose modifications, slot and base face machined and 2 holes drilled for M5 bolts

First job for me was to machine the block up on the Tormach CNC mill

.jpg)

Basic shape CNC'd out

One the basic shape was done it was turned over to machine to thickness then put back into the mill to machine the radius within the arms and the four holes.

The buffer casting was drilled in tow places for the locking studs

.jpg)

Drilling the stud holes in the buffer

.jpg)

Rough assembly less springs

.jpg)

Trial fit.

The buffer casting radius on the back matches that of the bed nose. Until I get the tender fitted to the locomotive I wont know what the optimum length of the arms are . From what I have seen they need to be shorter than they are in the picture but I will sort the correct length out when the tender is attached.