Smoke Box

The smoke box started as a flat plate laser cut with all the holes and apertures either cut out or partially cut to prevent any deformation when rolling. The plate was then rolled into a tube to form the outer shell

The rolled sheet showing various holes and cut outs still in some cases to remove.

I made extensive use of the laser cutter on this assembly and the next thing was to drill and locate the front plate onto the shell.

Unfortunately one thing I had not noticed when drawing up the shell was the as built was slightly different than the drawing. So it was a case of bring out your filler as the locomotives running around have only one row of rivets in the front .

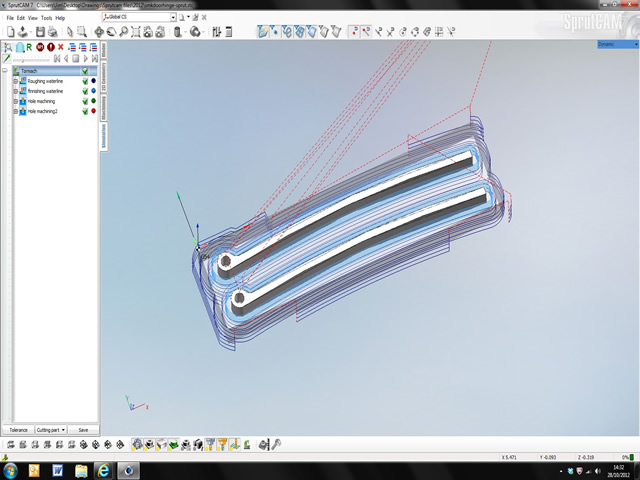

As I was looking for some jobs to do on my CNC mill one that looked interesting was the door hinges for the boiler door. There are plenty of alternative ways to make the hinges but as I had the technology it seemed worth a punt. So first thing as to prepare the Gcode using Sprutcam

Sprutcam tool paths dark blue is roughing cutter, light finishing cutter

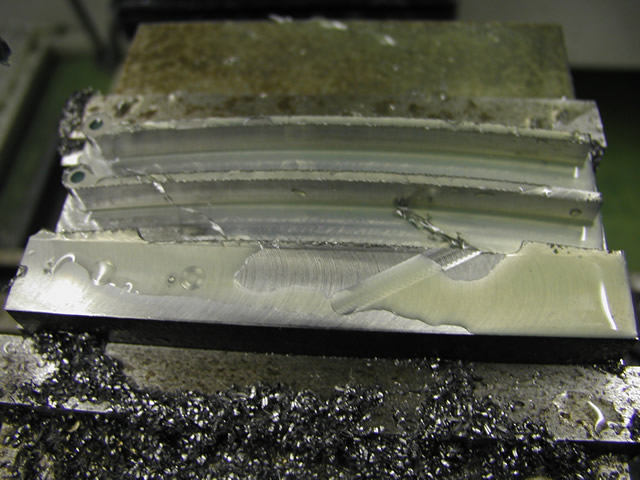

Start of the roughing process 8mm roughing mill at 12 inches per minute and 5000 RPM

Clean up cut using a 6mm cutter at 5 IPM and 4000RPM

I actually got to this point three times. The first time on the cutter melted about halfway down. I attempted to fit a new cutter but that did not go well and the piece was scrapped.

Second attempt again everything going like a charm, when the air compressor cut in and the computer and mill tripped out loosing everything including the job offsets so back to the drawing board

Third time although once again I melted the finishing cutter. But this time I just put a new one in and instead of running from here. Just started the whole run again cutting the roughing cut in air and then completing the final cuts as planned. So I guess actually that would be four times.

I discovered that the melting was due to me selecting an HSS cutter not the solid carbide ones I had purchased for the job. So probably speeds and feeds were a tad on the ambitious side for HSS.

Holes drilled ready to machine the back

Cleaning up the back and leaving a tab on each end to cut and file off

ready for cutting and filing

Job done

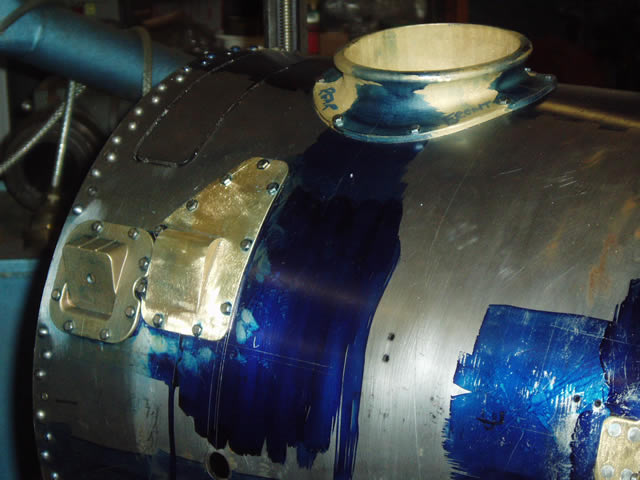

Next was are assembly of all the parts onot the smokebox superheater covers door etc

Chimney and Oakadee hinges fitted

Superheater cover and throttle cover