Tender

So I don't get too far ahead with the locomotive and not done anything on the tender I have started in a small way to get things moving. It also enabled me to spread costs again which is always important.

The design falls into three parts the tender bed, trucks and body. The trucks have been a source of some concern as they are quite complicated and are not symmetrical which has needed a bit of clever thinking to reduce the amount of parrtern work required.

The bed is a three piece construction front and end sills in cast iron connected with a hollow section tube frame. The frame further braced with laser cut ties and mounting points for the truck pivots. On other large models for instance the challenger and big boy the centipede tender bed has been made using a one piece aluminum casting. In this case as the tender is 6ftm, 2m long the cost and complexity required to produce a one piece casting would be more than I wanted to spend. Hence the cheaper built up construction I ended up with.

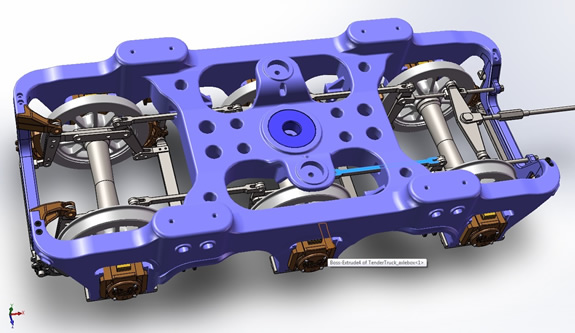

The tender trucks were the first dawning I did in 2000 and have been through innumerable iterations. Generally to try and reduce the cost due the their lack of symmetry. 2013 saw yet another go at getting a cost effective solution design, helped in no small part by Phil Monsborough who was able to 3D model the truck and generally from that we were able to come up with what I hope will be the last visit to this drawing board.

Phil's 3D model of the tender truck

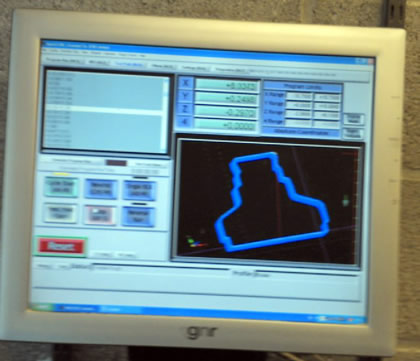

So first job was the front and hind sills which I was going to produce in C.I. From a pattern made by Eric Hales. Who once again through the www I came across. Eric was working with a CNC router and had many years of experience producing patterns. Eric used my 3D drawings to produce the tool paths and machining strategy's required to produce the patterns. Luckily for me the sills are relatively straight forward and I was able to do my own Solidworks modeling for this job.

.

G code for front sill

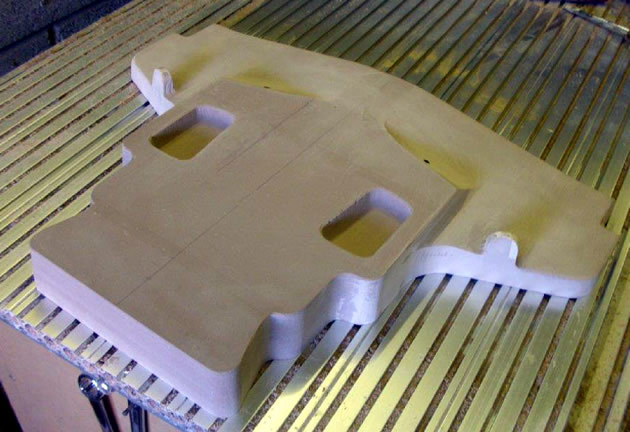

Basic shape appearing on the router

Main pattern starting to emerge

Pattern ready for the foundry

Front sill as cast

Next job Eric tackled was the hind sill in the same manner as the front working off the Solidworks drawing

Completed pattern for the hind sill

Hind sill

As both castings are CI they are relatively heavy, the tender is 20" wide and a big part of the work Eric did was to get the weight down as much as possible. Even so they are still a hefty lump. Eric's contact details are on my links page for anyone interested in getting some first class pattern making done.

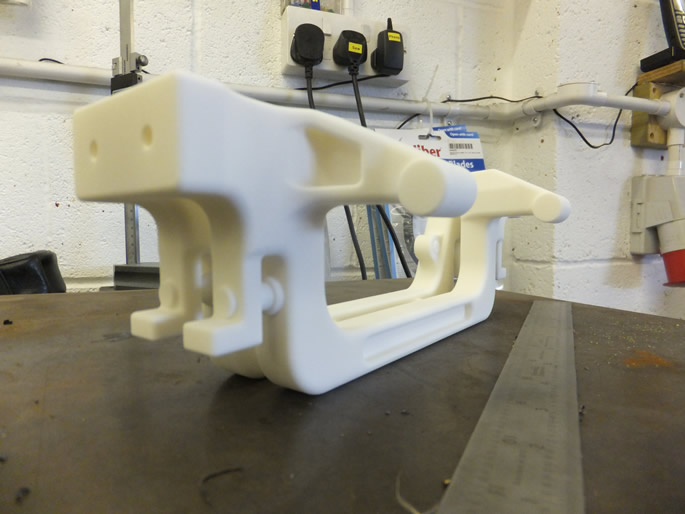

The truck is also under way and in 2014 I will decide who will be making the pattern. I have had the end sills which create the lack of symmetry done as an RP This means that hopefully the pattern will only need to model one side which can be duplicated for the other side. Although their might be a bit of water to flow under the bridge before I can land that one.

RP for end sills

The end sills due to some clever work by Phil have been joined together into one pattern for lost wax casting. The above photograph is the RP in nylon, I have then had a rubber mould made and the wax tooling has been produced from it. I am waiting for a price to produce in ether CI or bronze as this is written December 2013