Trailing Truck

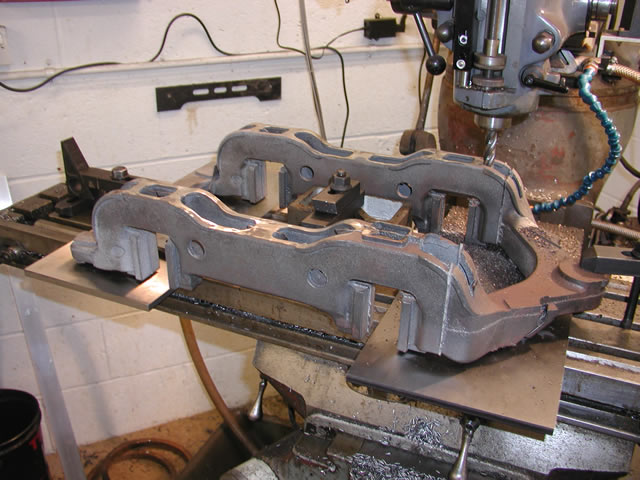

First job to tackle was to clean up the truck casting and machine the pedestal faces.

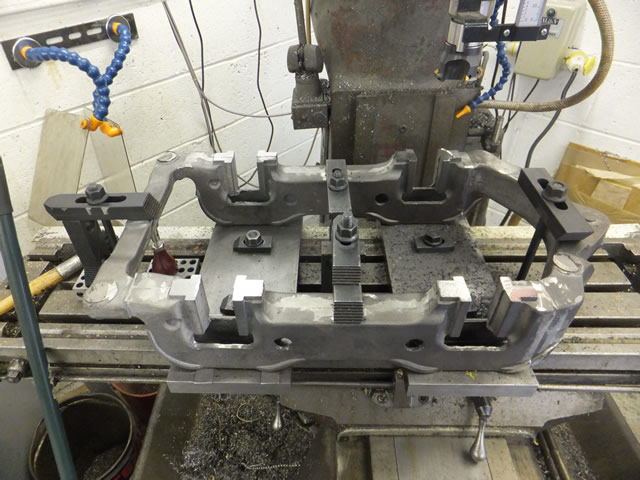

Tuck frame on the Bridgeport note table extensions !

Set up for cleaning up the pedestals

This was about as far as the machining went, as I found a major error in the casting. Well perhaps not the casting more the drawing. So very shortly this casting will be back in the pot and a new one from the modified pattern will emerge, so more of that later.

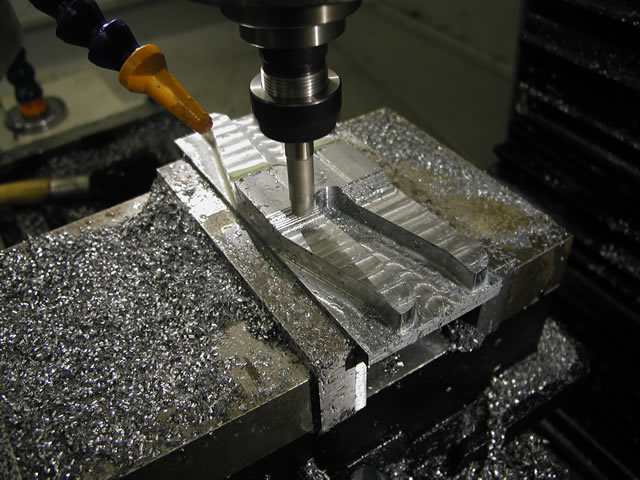

Just to keep things ticking over and to keep my learning curve on the up I did a bit of CNC work on the truck springing next.

Machining the first side

First side done

Cleaning off the back ready to machine the other side

Both sides done cleaning up the edge

Oilite bushes fitted for bearings

Next job was to start work on the axles

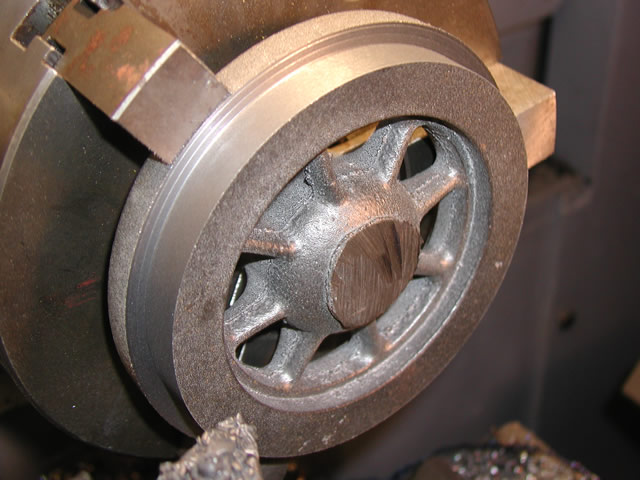

Facing up the castings and roughing the lyre diameter

7.1/4 and7.1/2 wheel blanks ready to fit to the axles

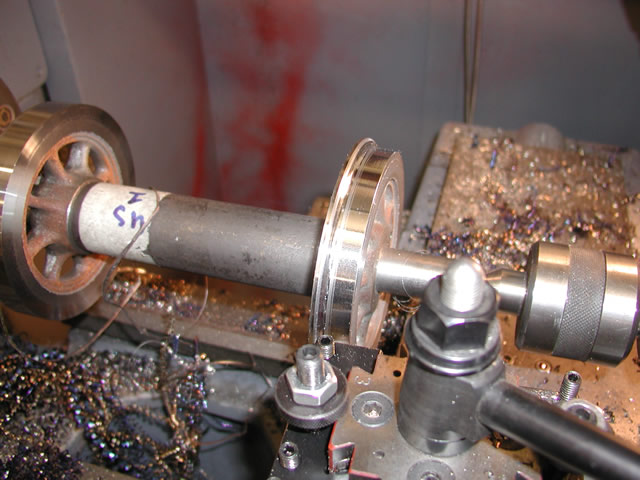

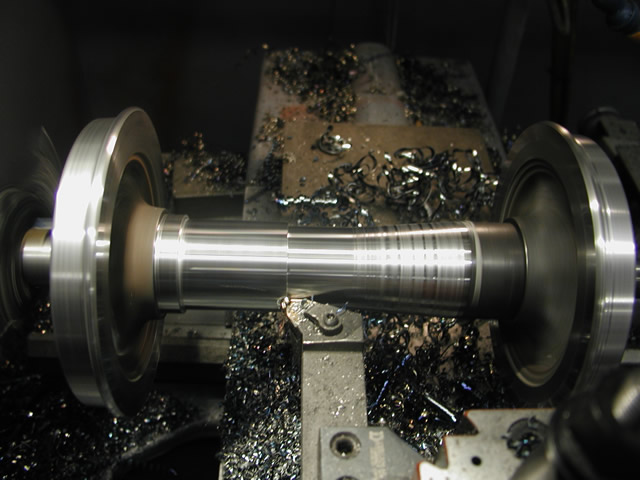

Making the axles

Once the axles were made next job was to press them onto the axles. From there i made up steel tyres to shrink on. Then it was time to skim the outside heat up the rings and fit

Cleaning up the outside diameter ready to fit the rings

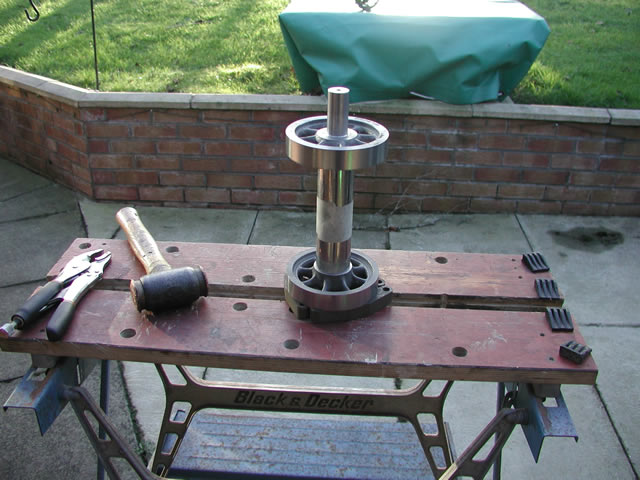

Sunny day so out the back ready for the rings marinating quietly at gas mark 9 in the oven

First end drops in

Both tyres fitted.

Checking the back to back measurment

Forming the tread

Waisting the middle of the axles

Both sets ready for painting